Andy Graves

Pronouns: he/him

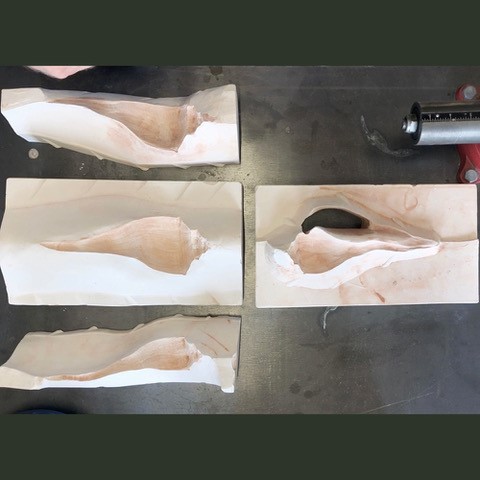

I slipcast porcelain clay. Slipcasting generally is a mass production system. Normally a positive model is molded with plaster. The slip clay which is liquid, is poured into the plaster mold and the porous plaster absorbs the water leaving a shell of clay behind. The excess liquid slip clay is poured out and the mold left for an hour or so to allow the clay shell time to harden slightly. Then the plaster mold is removed and the copy of the original model is left, cast in clay.

I do use the plaster in my molds but my process is much different. One main element I use is casting blocks of plaster that are machined by cutting, drilling etc on shop machines. I also cast organic or natural things that have interesting textures. Rotting wood, sea shells, burnt wood, carved or modeled materials are used. There are different means of molding them, sometimes directly into the plaster I will use for slipcasting. Other times I make rubber molds that I later make plaster parts with.

I have a store of many thousands pieces. I draw inspiration from various places. Many have come from objects I have visualized during guided meditation practices. Some inspired from architecture, nature, or other artists work. Some fill a need for an object and the form is visualized in the moment. Once I can visual a specific form I may need to build special mold parts to construct it. Or many times I am able to build it from my store of pieces. Either way, the mold is visualized and built in the negative. The “negative” to me is a nod towards the philosophical idea prevalent in Buddhism regarding the ultimate truth of all phenomena being “empty of self existence”. Deconstructing objects in my mind and rebuilding them in the negative allows me to keep a grasp on that idea that all things are not how they appear.

While constructing a mold I have to keep a hold on where I am in terms of what I see the finished piece to be. I use marks on the plaster, measuring sticks and various methods of keeping track. Mostly though, it’s in my mind. I prefer to only work on constructing a mold until it’s finished and not other tasks in the studio. It would be easy to lose track of where I am in the mold making. I can’t really see into the mold as it is built up.

I use many other materials in the construction of my molds. Pieces of card stock, foam, cloth, wood etc all to assist creating shapes that I could not do otherwise. I have also developed means of moving very large pieces after they are slip cast onto drying boards and then shelves that get fired (a freshly slipcase piece while still green or not fired yet is extremely fragile-one reason you don’t see pieces even as large as mine being slipcast-almost impossible to move). I use systems I borrow from my construction work. For example needle beams and various ways of shoring heavy buildings.

Bio

Builder

1981-present

Started in building when I was 15 and this year I’m turning 55.

I grew up north of Duluth, Mn, in the country on a 40 acre homestead. My first years working were mostly in carpentry. I learned carpentry, then management as a foreman and finally into project management. I have been working in NYC since ’96 as a project manager for a general contracting firm. Most of my projects are townhouse full renovations in Manhattan.

The take away from all I’ve done is that I’m mostly self taught. I love problem solving. Working with Architects and designers to take their visions from drawings to reality. I have a knack for spatial reasoning, sequencing projects and managing others.

Ceramicist

2012-present

Spent roughly 1 year learning clay hand building.

Had 3 years of slipcasting when I learned the basics of plaster mold making. I made a lot of molds with just about anything I could get my hands on to test myself and push the limits of plaster. Also learned the basics of working with slipcasting clay.

Somewhere around the end of 2015 I started inventing my modular mold making systems. During the last 4 years I have been focusing most of my attention on developing my processes with modular molds. Have been making what would be considered fine art with a hint of semi-functional collectable design.